Casting Defects

The following defects may be present in the material before any further processing operations such as forging or rolling have begun. All casting defects are therefore inherent.

Porosity

This is formed by gas which is insoluble in the molten metal. The gas is trapped within the metal when it solidifies and remains in the form of spherical or tubular cavities.

Airlocks

A cavity formed by air which has been trapped in the mould by the metal during pouring.

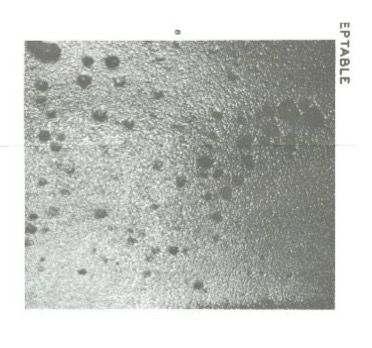

Blowholes

These are small holes near to or on the surface of the casting. They are caused by gas evolution from the decomposition of grease, moisture etc. but not from the mould itself.

For example, during the sand casting operation, moisture from the mould produces steam, this is normally forced through the mould due to the absorbent nature of the sand but sometimes the steam cannot get through to the outside and is forced back into the casting, blowing holes in the casting surface. There is an increased possibility of this occurring in hand produced sand moulds on the cross sectional changes, where the operator has compressed the material too much whilst trying to pick up the change of section.

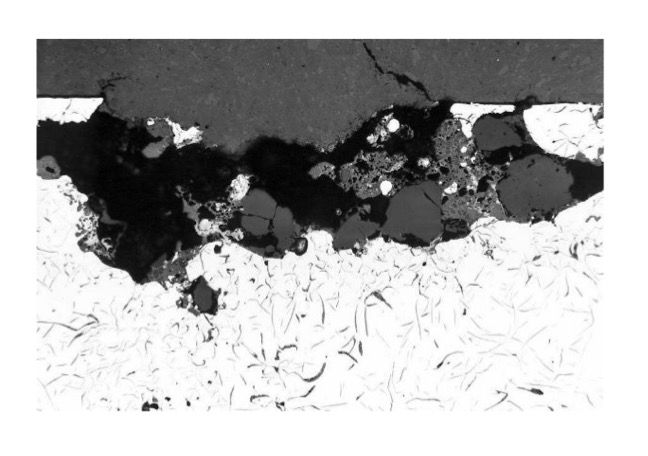

Non-metallic inclusions

Non-metallic inclusions are impurities such as slag, oxides and sulphides, which exist in the molten metal and finally the solidified metal.

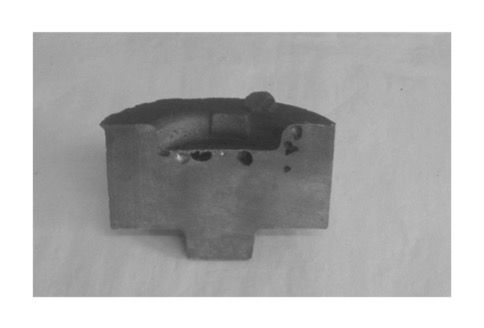

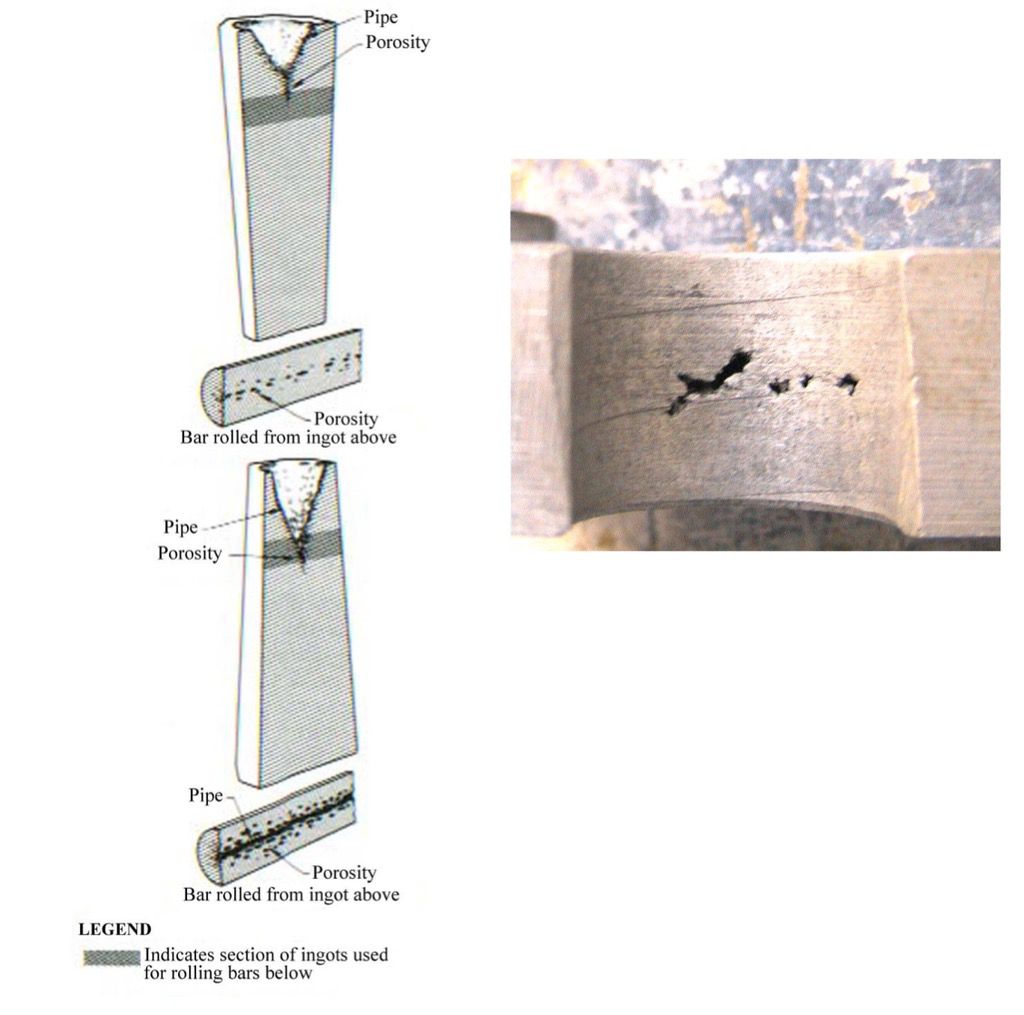

Pipe/shrinkage defects

This is a cavity in the centre of the ingot/casting caused by shrinkage during solidification. A primary pipe defect is surface breaking and secondary pipe defect is one that exists sub-surface. The top of an ingot casting is removed to get rid of the primary and secondary (if existing) pipe prior to rolling.

Other shrinkage defects may occur in steel castings where there is a localised variation in section thickness. Shrinkage defects are not normally associated with gas, but a high gas content will magnify their extent.

Interdendritic shrinkage: very small shrinkage cavities associated with dendrite solidification.

Segregation

Segregation is chemical heterogeneity, or the non-uniform distribution of the alloys or impurities. Pure metals do not exhibit segregation.

In carbon steels, the elements which segregate are those that are either insoluble or form lower freezing point complexers, e.g. sulphur, phosphorus, carbon, manganese and silicon.

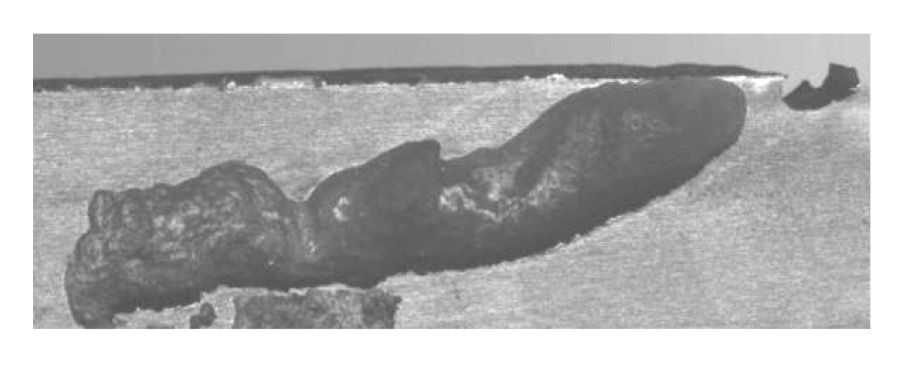

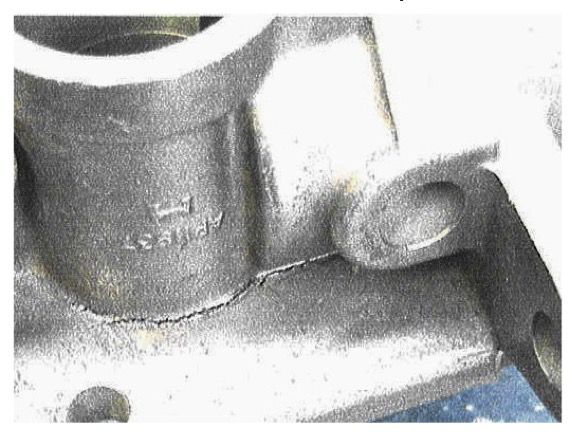

Cold shuts

A cold shut is an area where two or more streams of metal meet within the mould however they do not fuse together this may be surface breaking or sub-surface in a casting. Cold shuts may result from splashing, surging, interrupted teeming or the meeting of two streams of molten metal coming from different directions, usually where casting temperature is too low or poor mould design using multiple feeders which are positioned too far apart.

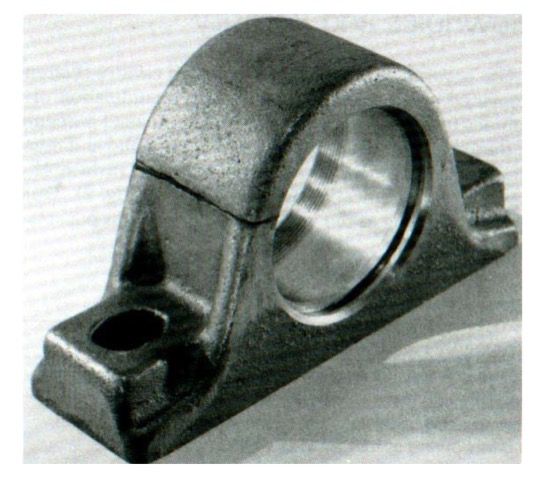

Hot tears (cracks)

Cracks caused by non-uniform cooling resulting in stresses which may or may not rupture the surface of the metal while its temperature is still in the brittle range. They appear as ragged lines of variable width and numerous branches.

The tears may originate where stresses are set up by the more rapid cooling of thin sections that adjoin heavier masses of metal, which are slower to cool. Curved surfaces and corners tend to promote hot tearing.

Sinks

Sinks are depressions on the surface of the casting due to shrinkage or the presence of a fault such as porosity below the sink.

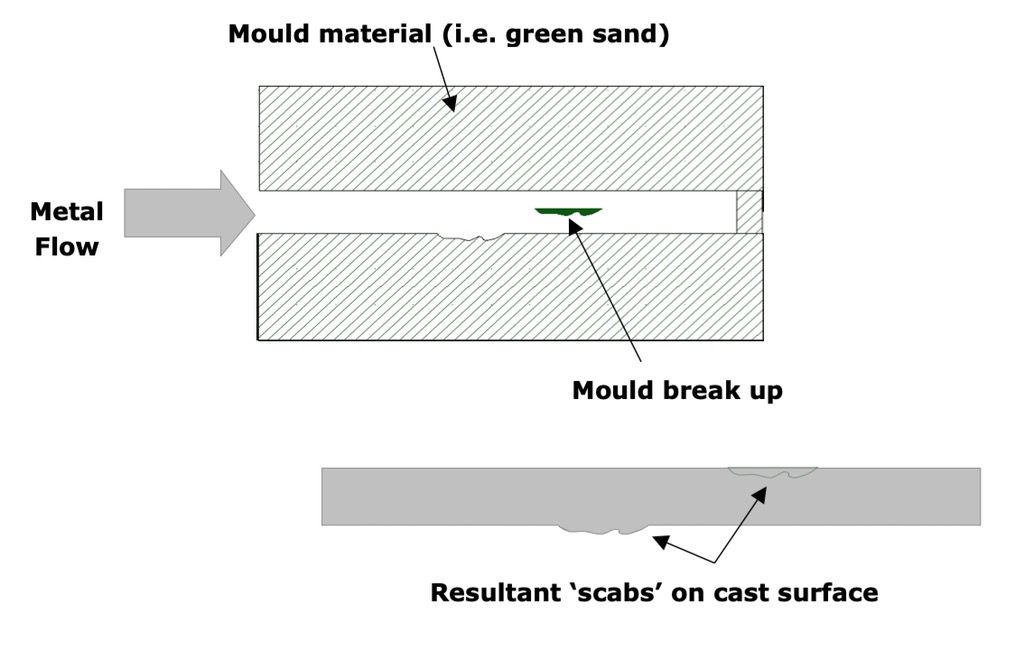

Scabs

Scabs are formed when the mould wall breaks away into the mould cavity. The mould wall material combines in to the castings surface, or the molten metal flows into pit left by the breakup which combines both the metal and sand inclusion matter.

Superheat

Superheat occurs when the material is heated beyond the temperature required to melt it, as it cools the result is excessively large grain structures. The only exception to this is aluminium. It also increases the probability of shrinkage defects forming due to increased contraction rates.